Hand over the money!

The Pessac facility is responsible for manufacturing euro coins for circulation in France, as well as minting foreign currencies. It manages the entire production process, from cutting the blanks (pieces of metal that are shaped and weighed before being transformed into coins) to packaging the final product. Every year, over 1.6 billion circulating coins are minted at Pessac, with two-thirds destined for export.

Why is it important to preserve this heritage?

The Monnaie’s factory at 11, Quai de Conti in the French capital hosts the Musée de la Monnaie de Paris, a mint museum dedicated to the art of metalworking. This one-of-a-kind experience combines exhibition spaces with a glimpse into some of the factory’s workshops. The exhibition route explores a wide range of disciplines (including art, science and technology, the history of peoples, taste and economics, as well as archaeology and sociology) that reflect the richness and diversity of the Monnaie de Paris’s collections and celebrate the men, women and professions that uphold its exceptional craftsmanship.

Everyone is free to explore the museum’s collections online and even visit virtual exhibitions thanks to a digital portal dedicated to the museum’s historical holdings (which are growing year after year).

Contract for digitising artefacts in situ

The initial phase of the project, set for 2025, will focus on digitising the first 1,500 dies, and will generate 5,000 digital views. Each tool will be photographed from three angles: axial, three-quarter and side view.

Our on-site team will set up a custom-built photographic studio on the Pessac site, which is home to the entire collection. This will consist of:

- One Phase One digital camera, which will be used to capture axial shots of the impression.

- One ScanCube scanner for 2D imaging with optimal lighting thanks to its reflective panels.

The technical hurdles

- Document the materiality of the objects by capturing all the details and markings, including on the secondary sides of the tooling.

- Capture axial views (of impressions), a three-quarter view, and – where necessary – an additional side view to reveal any inscriptions that are absent from the three-quarter shot.

- Factor in special cases for dies coated with varnish or grease as well as polished dies, where colorimetry or lighting will be required.

Additional refinement will also be called for during post-processing, which will take place in the Arkhênum workshops:

- Centimetre scale embedded onto the cropped image

- Embedding of the object’s inventory number

What does 2026 hold in store for us?

This project to digitise coining dies is a first for Arkhênum, which has traditionally focused more on digitising coins. It is an exciting challenge for our technical and R&D teams to test the limits of existing and future technologies as well as our production processes.

Do you have any unusual projects you would like to discuss with us? Click here to get in touch

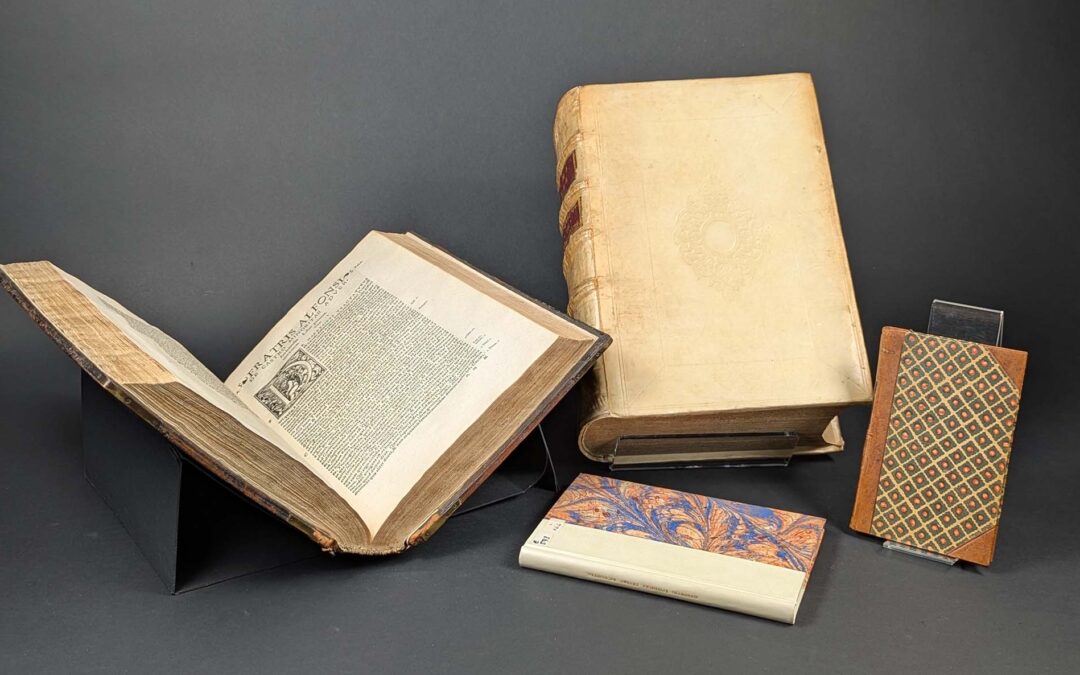

Every page turned is an archived story

Delivering state of the art heritage digitisation services worldwide

A MEMORIST company, Arkhênum has been providing digitisation and sharing services for heritage and industrial collections for over 25 years. Our services are carried out either in our own workshops or directly on site, wherever our clients may be. Watch our video to...

Maison d’Érasme shines a light on its censored texts

Arkhênum has just started a new project in Belgium at the Maison d'Érasme museum in Anderlecht. This commission is unique in a number of ways: First, due to the specialised processing of the collections (object-mode digitisation followed by page-by-page digitisation...

True Life in God: an AI-enhanced project

MEMORIST, in partnership with its subsidiary Arkhênum, recently undertook a project for the Swiss foundation True Life in God. From analysing the foundation’s requirements to digitising its collections for hosting online, this large-scale project required end-to-end...